Client name: Confidential

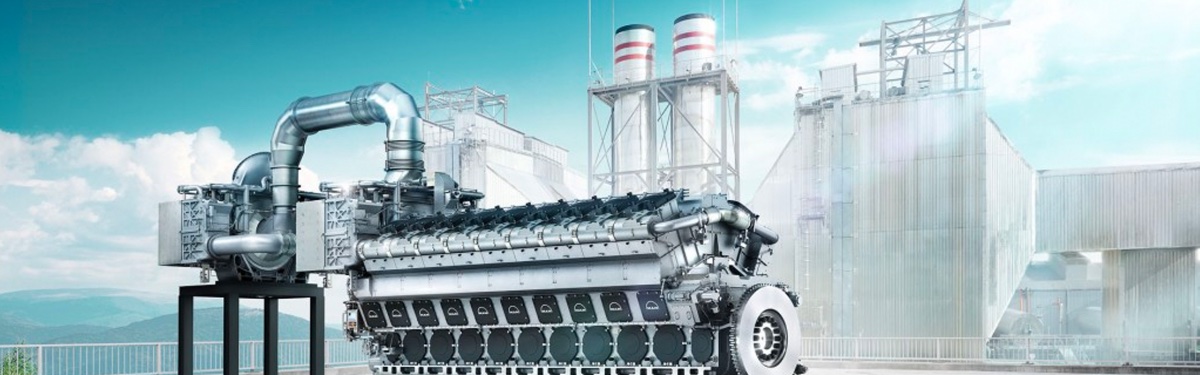

Name of the project: Construction of the Bellefontaine and Pointe Jarry power plants on behalf of EDF Production Electrique Insulaire

Description of project and customer issues

The company concerned is a German company specialising in the engineering and construction of industrial vehicles (trucks and buses), diesel engines and turbomachinery. In 2008, EDF PEI awarded a consortium a contract for the turnkey delivery of three thermal power plants with a unit capacity of 220 MW (Réunion, Martinique and Guadeloupe). The company concerned, acting as the leader of this consortium, entrusted Aegide International with a technical assistance mission for the projects in Martinique (Bellefontaine) and Guadeloupe (Pointe Jarry).

During the period February 2013-July 2015, Aegide International seconded one of its employees to successively ensure the HSE management of these 2 projects.

Activities / Tasks and Solutions developed by Aegide International

Manager HSE et interlocuteur HSE du groupement concerné vis-à-vis de la Direction de projet d’EDF PEI et des membres du groupement.

- Guarantor of the risk management policy during the construction, pre-commissioning, commissioning and start-up phases of commercial engine operation

- Deployment of HSE MS with monitoring & management of EDF contractual requirements

- Risk analysis and definition of preventive measures Drafting of the Site Emergency Plan and updating of the Prevention Plans and the PPSPS

- Documentary verification as part of the Intervention Request procedure, management of on-site coactivity and consignment requests (120 permits per day at peak activity)

- Encadrement de superviseurs HSE et coordination des actions HSE pour le groupement (13 Superviseurs HSE et 2 infirmières en Martinique – 15 Superviseurs HSE et 1 infirmière en Guadeloupe).

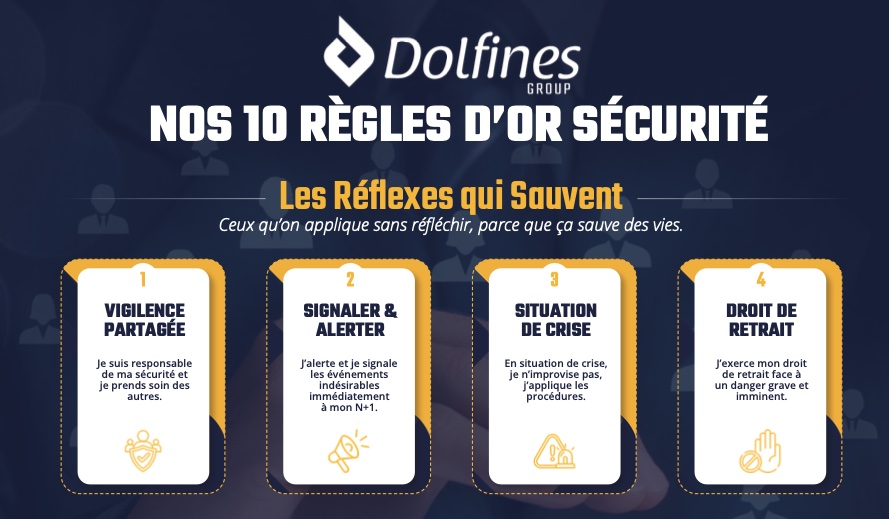

- HSE animation (customer HSE meeting, partner HSE meeting, Hierarchical Safety Visit, Behavioral Safety Visit, safety flash, information note on risks, treatment of malfunctions, co-facilitation of the CISSCT)

- Implementation and monitoring of action plans

- Steering and monitoring of indicators with reporting

- Post-accident analyzes (ATSA, ATAA), near misses and dangerous situations